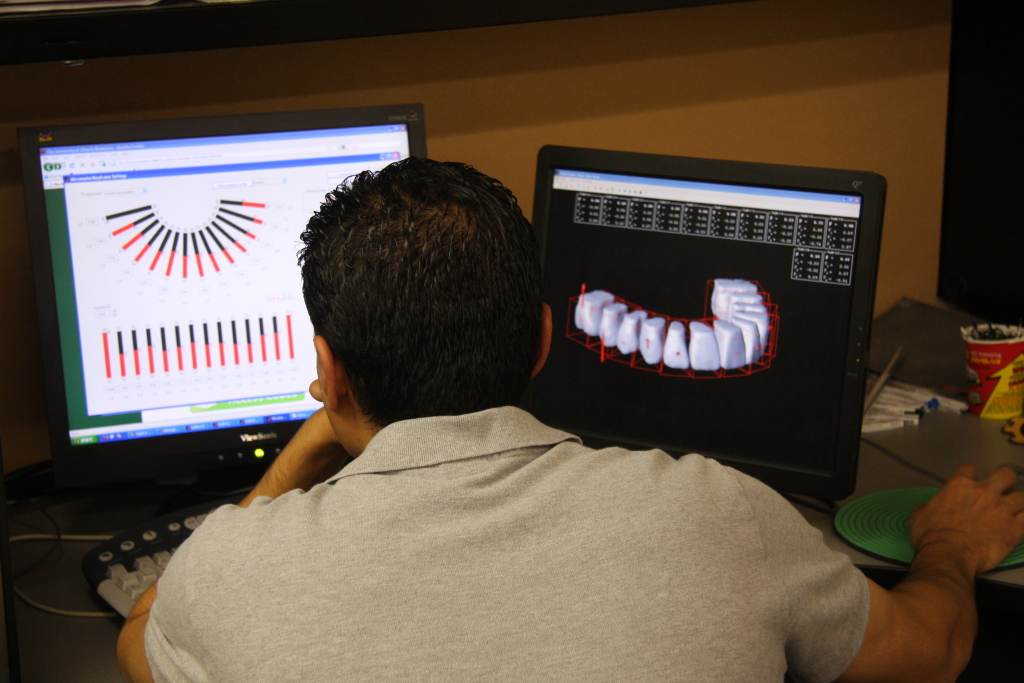

In 2012, Dr. Badawi began the development of a parametric clinical documentation method for efficient and standardized clinical documentation in clinical practice. He built an immersive user interface, intuitive to the niche orthodontic clinical user, to produce standardized and accurate documentation of the “clinical user actions.” By the end of 2012, Dr. Badawi developed the alpha and beta versions of an application designed to track the clinical actions performed on teeth in a real-life clinical setting. His first patent application was in 2013, and by 2014 he had a fully functional app used as a chair-side clinical sensor (a.k.a. Ortho4D), which enables the orthodontic healthcare provider to document seamlessly and efficiently, while producing highly structured precision clinical data.

Acquiring four granted US patents, Dr. Badawi gained a great deal of experience in the patents lifecycle, from ideation, IP reporting, patent searching, and the patent application process. He built a small but valuable portfolio of patents around object-oriented parametric clinical documentation and computer-assisted clinical documentation methods.

– United States Patent (USPTO) 9158889

– United States Patent (USPTO) 9792413

– United States Patent (USPTO) 10090070

– United States Patent (USPTO) 15/705476

Currently under development by Dr. Badawi:

– Advanced Minimally Invasive Aligner Protocols: Simultaneous aligner mechanics & sequencing protocols.

– Force-driven, selective moment vectoring. Rotations first treatment paradigm.

– Vectoring Orthodontic Tooth Movement, selective moment tooth movement.

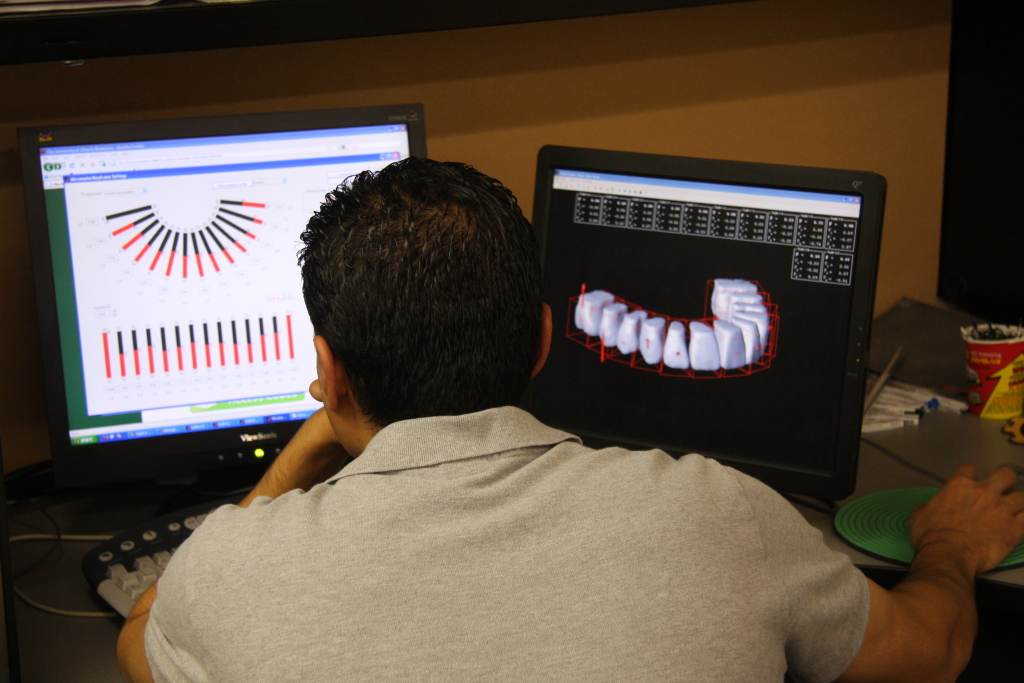

Dr. Badawi gained a great deal of experience in many areas covering a wide range of specialties including material sciences, mechanical engineering, signal conditioning, visual metrology, reverse engineering, data visualization, rapid prototyping & 3-D printing, application development, and cloud development. In addition to this, he received advanced Ph.D. level training in epidemiology, applied biostatistics, as well as completing a three-year residency program in clinical orthodontics. Dr. Badawi’s Ph.D. research was conducted almost in its entirety within the University of Alberta’s Faculty of Mechanical Engineering. The objective of his Ph.D. research was to devise an in vitro research instrument to quantify accurately and simultaneously, in 3D, the force systems applied on 14 artificial teeth arranged to simulate real-life orthodontic problems. He then presented the force and moment vectors visually on a graphical representation of the simulated dental arch.

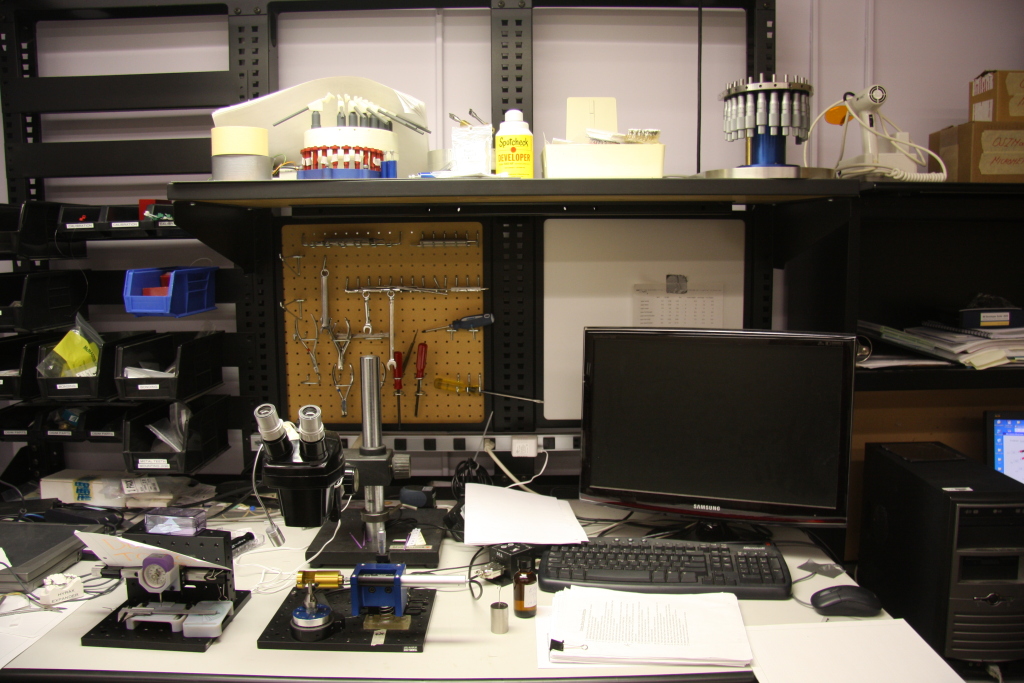

The University of Alberta provided an excellent venue for Dr. Badawi to learn the fundamentals of many domains and develop an in-depth understanding of key areas in mechanical engineering, material sciences, force transducer technology, and all aspects of data operations from data acquisition, signal conditioning, data processing to data visualization.

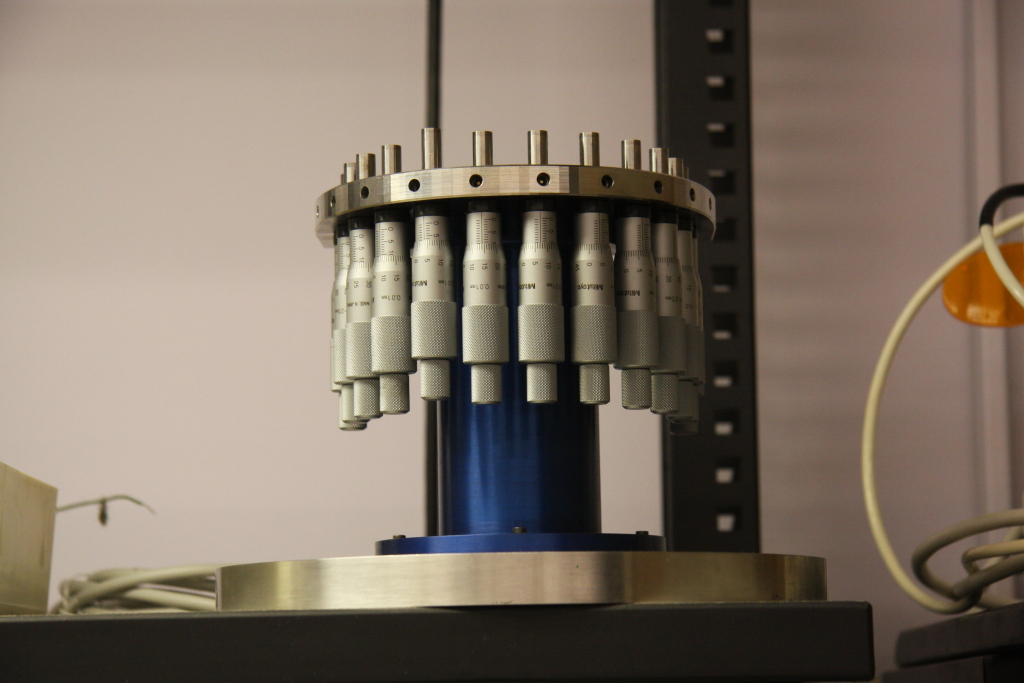

To build the OSIM device, Dr. Badawi had to solve several problems simultaneously.

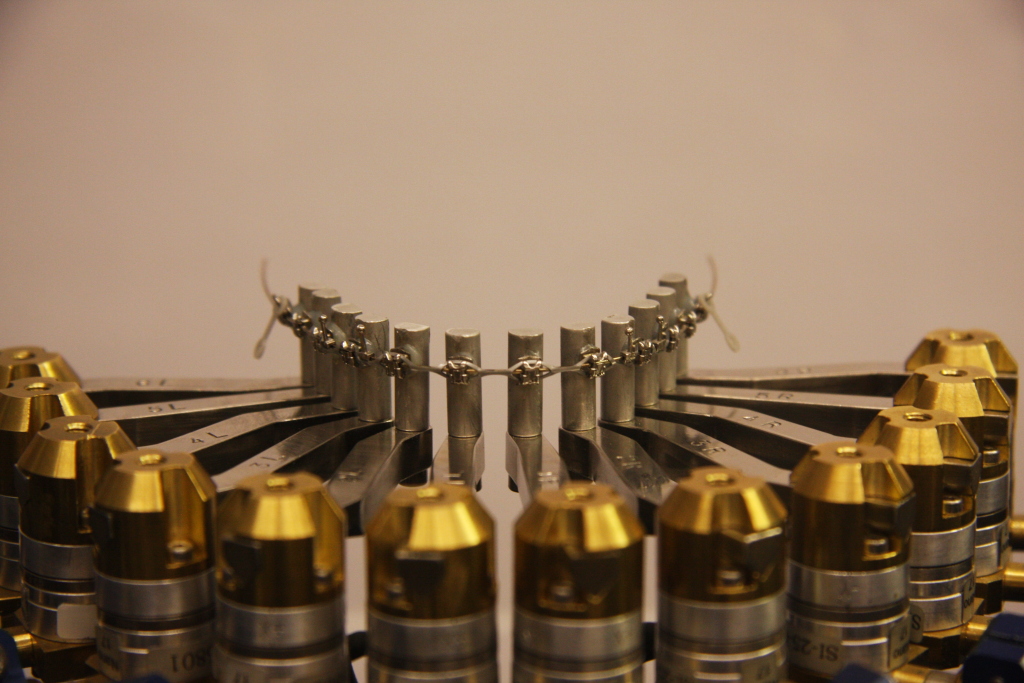

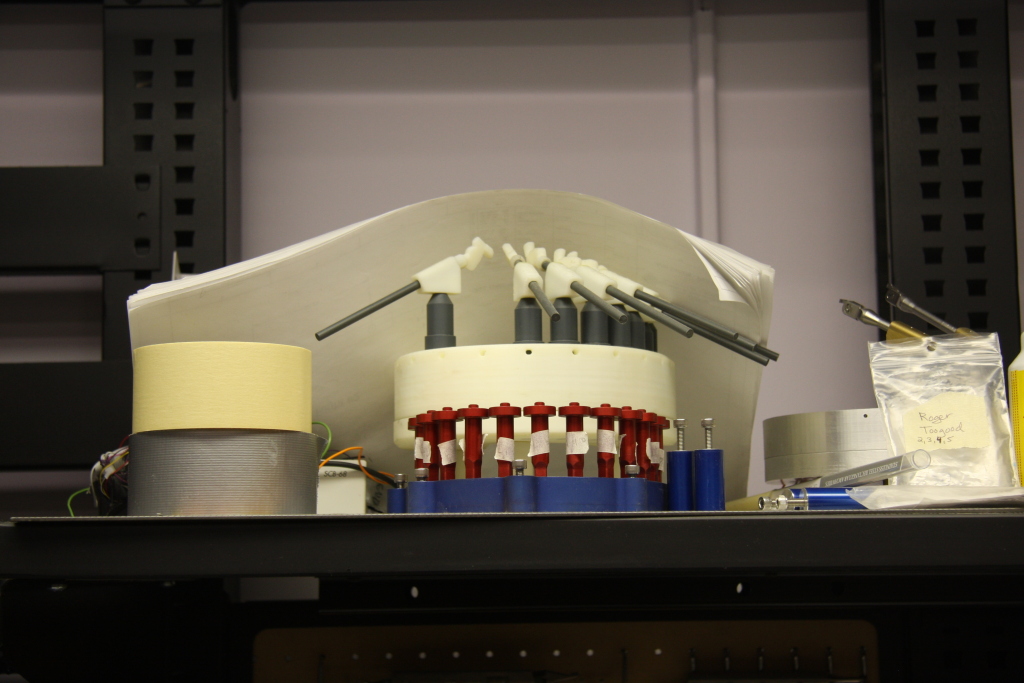

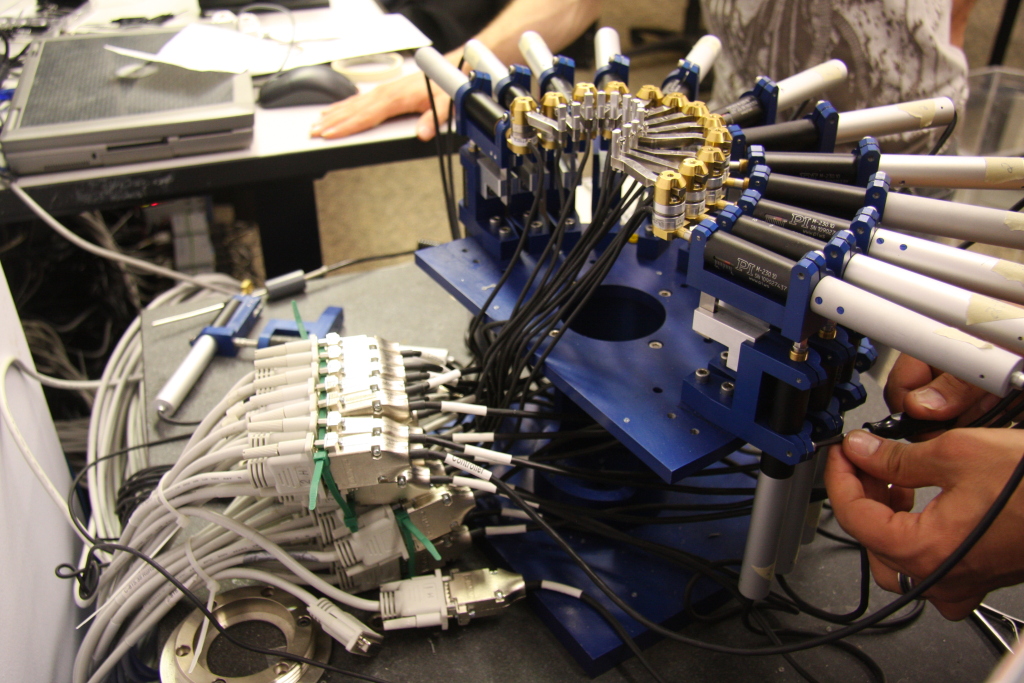

Dr. Badawi worked with a group of mechanical engineers and technical machinists to design the various mechanical components of the OSIM. The objective was to arrange the 14 multi-axis force transducers to connect each sensor to its designated tooth, special attention was paid to the 3D transducer placement relative to the artificial teeth, with the purpose of having the smallest possible distance from the tooth (point of force system application) to its designated transducer. Rapid prototyping was used to go through a few design iterations before settling on the final design and starting production of OSIM parts in the mechanical engineering machine shop.

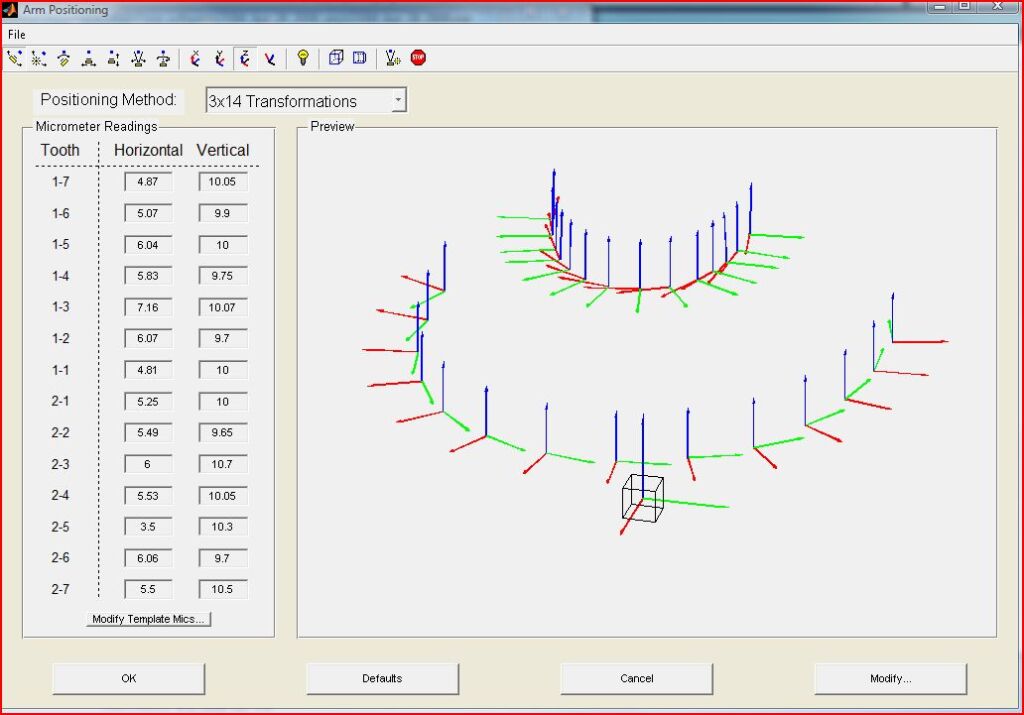

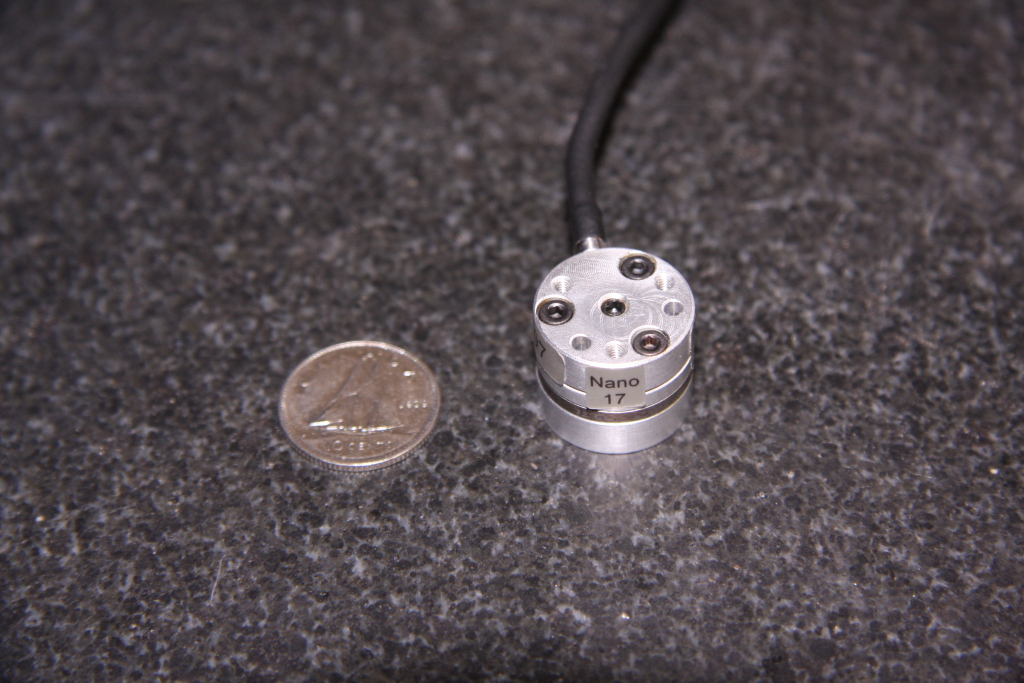

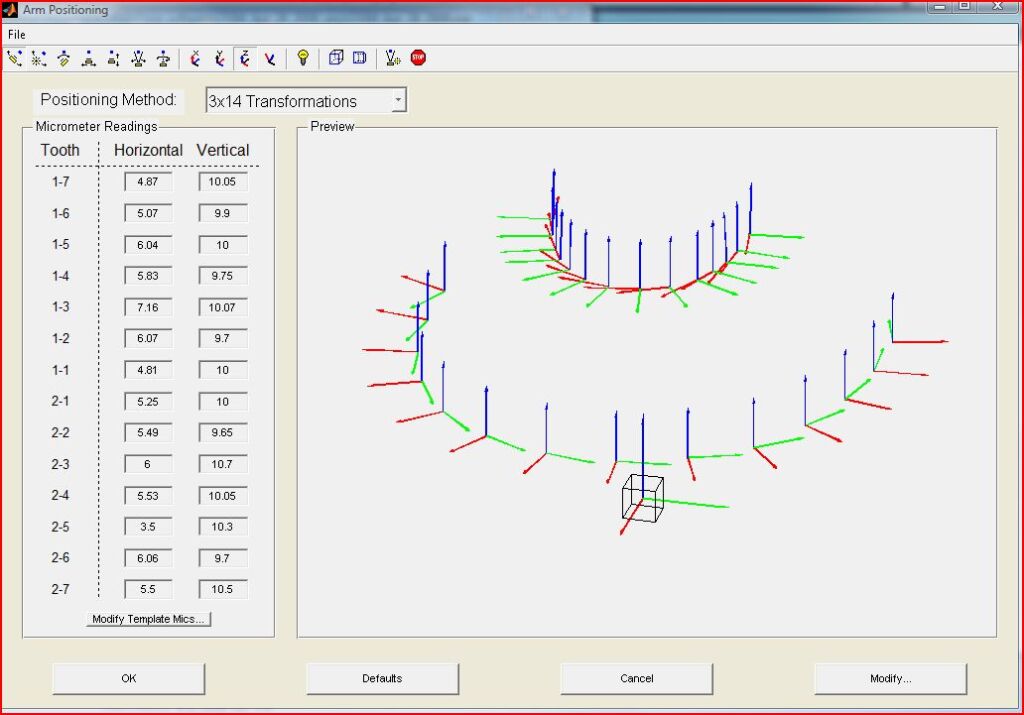

Dr. Badawi and his team used 14 multi-axis force transducers (Nano17, ATI automation), and solved the challenge of connecting multiple transducers to a single PC using a multiplexer and high-speed data acquisition card. Gained hands-on experience using a coordinate measurement machine (FaroArm) with a laser scanner, the purpose of which was to accurately measure the position of the artificial teeth (point of force application) relative to the transducer’s coordinate frame. These measurements were used to build the transformation matrices used for forces system transformation from the sensors coordinate frames to the artificial teeth coordinate frames.

This posed as a significant challenge to Dr. Badawi due to the vast amount of data collected simultaneously from 14 transducers. Utilized specialized instruments for data acquisition hardware with specialized data acquisition software, to collect all the signals from the 14 sensors (a total of 84 channels), used Labview to acquire the signals and apply the designated calibration for each of the transducers. Carried out detailed error analysis using a custom designed device to apply known force or moment to each of the sensors six axes (Fx, Fy, Fz, Mx, My, Mz).

Dr. Badawi also led the creation of a custom application for force system data visualization to display the orthodontic force and moment vectors in a 3D visual dental arch simulation, completing the process of reverse engineering orthodontic force systems. Gained considerable hands-on experience in computer graphics, WebGL, 3D editors, 3D metrology, reverse engineering, and gaming 3D graphics technologies.

– Major PW, Toogood RW, Badawi HM, Carey JP, Seru S. Effect of wire size on maxillary arch force/couple systems for a simulated high canine malocclusion. JOrthod. 2014 Dec;41(4):285-91. 2014

– Analysis of maxillary arch force/couple systems for a simulated high canine malocclusion Part 1. Passive ligation. Foka J, Toogood RW, Badawi H, Carey JP, Major PW, Angle Orthodontist. 2011

– Analysis of maxillary arch force/couple systems for a simulated high canine malocclusion Part 2. Elastic ligation. Foka J, Toogood RW, Badawi H, Carey JP, Major PW, Angle Orthodontist. 2011

– Measurement of orthodontic bracket tie wing elastic and plastic deformation by arch wire torque expression utilizing an optical image correlation technique. Lacoursiere RA, Nobes DS, Homeniuk DL, Carey JP, Badawi HH, Major PW. J Dent Biomech. 2010

– A comparison of torque expression between stainless steel, titanium molybdenum alloy, and copper nickel titanium wires in metallic self-ligating brackets. Archambault A, Major TW, Carey JP, Heo G, Badawi H, Major PW. Angle Orthod. 2010 Sep;80(5):884-9.

– Authors' response. Appearances count when industry underwrites research. Badawi HM, Major PW. Am J Orthod Dentofacial Orthop. 2010 Apr;137(4):444-6.

– Three-dimensional orthodontic force measurements. Badawi H, Major P. Am J Orthod Dentofacial Orthop. 2010 Mar;137(3):299-300

– Torque expression in stainless steel orthodontic brackets. A systematic review. Archambault A, Lacoursiere R, Badawi H, Major PW, Carey J, Flores-Mir C. Angle Orthod. 2010 Jan;80(1):201-10. Review.

– Three-dimensional orthodontic force measurements. Badawi HM, Toogood RW, Carey JP, Heo G, Major PW. Am J Orthod Dentofacial Orthop. 2009 Oct;136(4):518-28.

– Torque expression of self-ligating brackets. Badawi HM, Toogood RW, Carey JP, Heo G, Major PW. Am J Orthod Dentofacial Orthop. 2008 May;133(5):721-8.

– Clinical variability in arch wires: a preliminary study evaluating mechanical and surface characteristics of two different sized rectangular stainless steel wires. Vena A, Carey J, Badawi H. Open Biomed Eng J. 2007 Aug 3;1:13-22.

– The effect of orthodontic bonding materials on dental plaque accumulation and composition in vitro. Badawi H, Evans RD, Wilson M, Ready D, Noar JH, Pratten J. Biomaterials. 2003 Aug;24(19):3345-50.

– New testing approaches and characterization methods for arch wires: preliminary study using different steel wires. Badawi H, Carey J, Major P. The Open Biomedical Engineering Journal, 2007,1, 13-22

– Effect of Wire Size on Maxillary Arch Force/Couple Systems for a Simulated High Canine Malocclusion. Paul W. Major; Roger W. Toogood; Hisham M. Badawi; Jason P. Carey; Surbhi Seru Journal of Orthodontics

HOURS OF OPERATION

Monday: admin day

Tuesday: 9:00-17:00

Wednesday: 9:00-17:00

Thursday: 7:30-15:30

Friday: 7:30-15:30